Remediation systems

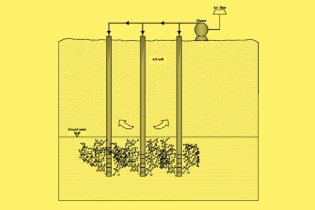

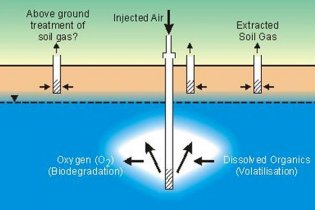

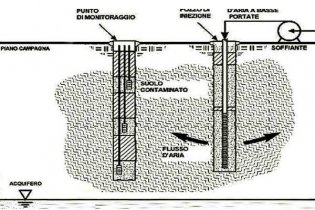

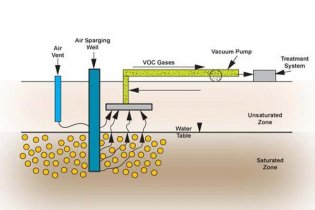

Air Sparging (AS)

The technology involves the insufflation of air into the contaminated aquifer, in correspondence of properly equipped wells.

- Effectiveness of Air Sparging

- Stripping of volatile compounds

- Support for biodegradation reactions

The extraction of insufflated gas usually takes place through the joint action of a system SVE system

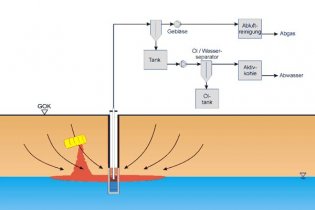

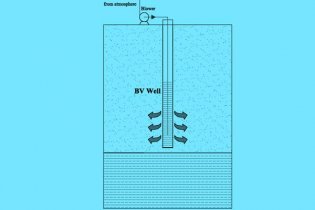

BioSlurping (BSL)

The technology allows the recovery of floating product (hydrocarbons) on the groundwater table, by the action performed by a surfasse suction pump.

- Benefits of the BioSlurping system

- High efficiency purification

- Possibility to recover the extracted product

- Contextual extraction of interstitial gas

The technology is particularly convenient in case of low aquifer permeability.

BioVenting (BV)

BioVenting involves the insufflation of oxygen in the subsoil, thus favoring the action of bacterial degradation.

Applicability of BioVenting:

- High biodegradability of contaminants

- Average / slightly cohesive soil

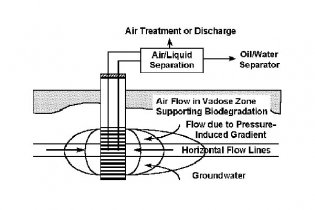

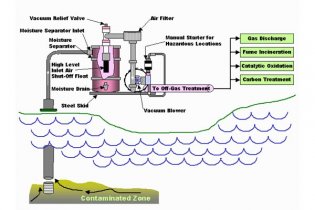

Soil Vapor Extraction (SVE)

This method involves the installation of extraction wells, for the decontamination of polluted vadose zones.

The wells are maintained in depression by the suction of the gas. How does the recovery happen?

- Physical extraction of pollutant

- Soil oxygenation

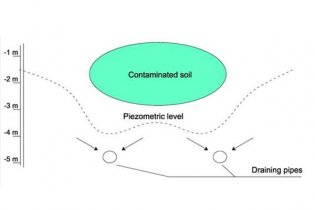

Deep LandFarming (DLF) ®

The Deep LandFarming ® is a patented technology by Water & Soil Remediation.

Main features::

- Achieving greater depths

- Low cost of installation and operation

- Easy to implement

- Effective on organic compounds

- Effective even on surface aquifer

Implementation:

- Preliminary dewatering (by draining pipes or wellpoint system)

- Preparation of piles and installation of the air injector pipes

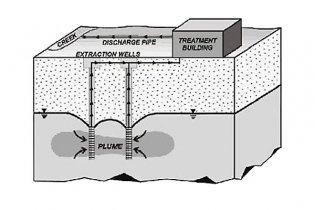

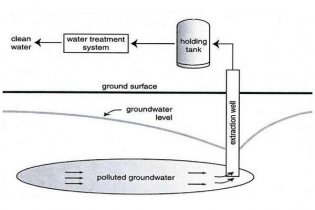

Pump & Treat (P&T)

With the Pump & Treat system contaminated water is extracted and subsequently treated.

Benefits of Pump & Treat technology:

- Extraction of heterogeneous contaminants

- Contamination migration inhibition (hydraulic barrier)

- Recovery of treated waste water